Complete Guide to PCBA and JST Connector Types: What You Need to Know

In the fast-evolving world of electronics manufacturing, understanding how individual components and assembly processes come together is essential for ensuring performance, quality, and reliability. Two fundamental concepts that play a crucial role in product development are Printed Circuit Board Assembly (PCBA) and JST connectors. This article provides a complete overview of what PCBA involves, the role JST connectors play in electronic designs, and how both elements are closely related in modern electronics.

What Is PCBA?

Printed Circuit Board Assembly (PCBA) is the process of populating a bare printed circuit board (PCB) with electronic components to create a functional circuit. Unlike PCB fabrication, which refers to the production of the physical board itself, PCBA refers to the full assembly process that includes the placement and soldering of components onto the board.

The typical PCBA process includes:

- Solder Paste Application: Solder paste is applied to the PCB pads using a stencil.

- Component Placement: Components are placed onto the board using surface-mount technology (SMT), through-hole insertion, or a combination of both.

- Reflow or Wave Soldering: Soldering methods vary based on the component type and design; reflow soldering is common for SMT, while wave soldering is used for through-hole components.

- Inspection and Testing: Quality control procedures such as Automated Optical Inspection (AOI), X-ray inspection, and functional testing are conducted to ensure performance.

PCBA is critical for the development of any electronic device, from simple consumer products to complex industrial systems.

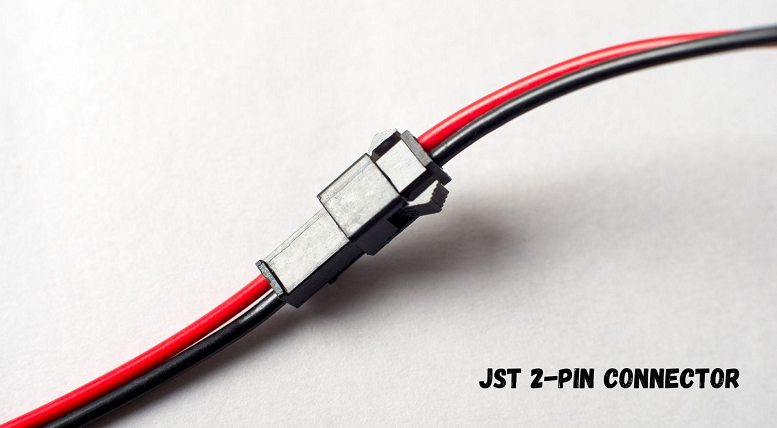

Understanding JST Connectors

JST connectors are a family of electrical connectors manufactured by Japan Solderless Terminals. These connectors are widely used in PCBA due to their compact size, reliability, and ease of use. They serve as interconnection solutions between PCBs and various components such as batteries, sensors, and control units.

JST connectors are designed to meet the demands of modern electronics where space is limited and a secure, vibration-resistant connection is required. These connectors are available in various series and configurations to suit different voltage, current, and mechanical requirements.

Common Types of JST Connectors

There are several types of JST connectors commonly used in PCBA. Each type is identified by its series and defined by specific pitch sizes and electrical characteristics. Some of the most frequently used JST connector types include:

- JST PH Series (2.0 mm pitch): Popular in battery connections and compact electronics.

- JST XH Series (2.5 mm pitch): Commonly found in LED lighting and consumer electronics.

- JST SH Series (1.0 mm pitch): Suitable for high-density, space-saving designs such as cameras and wearable devices.

- JST SM Series (2.5 mm pitch): Frequently used in remote control vehicles and drones.

- JST ZH Series (1.5 mm pitch): Utilized in sensors and other low-profile applications.

Each connector type is selected based on the specific needs of the project, including current load, board space, and ease of assembly.

The Relationship Between PCBA and JST Connectors

JST connectors are often a standard part of PCBA, especially in applications requiring modular design or field-serviceable connections. Integrating the right connector type during the assembly phase is crucial for overall system functionality and serviceability.

When selecting JST connectors during the PCBA process, engineers must consider:

- Mechanical Fit: Ensuring the connector fits within the allocated PCB area.

- Electrical Requirements: Voltage and current ratings must meet application needs.

- Environmental Factors: Exposure to heat, moisture, or vibration may affect connector choice.

- Assembly Compatibility: The connector must be compatible with SMT or through-hole assembly methods used in the production process.

Correct connector selection not only improves the reliability of the assembled board but also simplifies testing, repair, and future upgrades.

Conclusion

A strong understanding of both PCBA and JST connector types is essential for anyone involved in electronics design or manufacturing. PCBA transforms design concepts into functional devices, while JST connectors ensure dependable electrical connections within those devices.

As electronic products continue to shrink in size and increase in complexity, the importance of choosing the right assembly processes and interconnect components becomes even more critical. From early prototyping to final production, attention to detail in both PCBA and connector selection can make the difference between a successful product and one prone to failure.

Whether you are an engineer, product designer, or procurement specialist, mastering the basics of PCBA and JST connectors will enhance your ability to build better, more reliable electronic systems.