Why Robotic Welding Systems is Transforming Modern Manufacturing

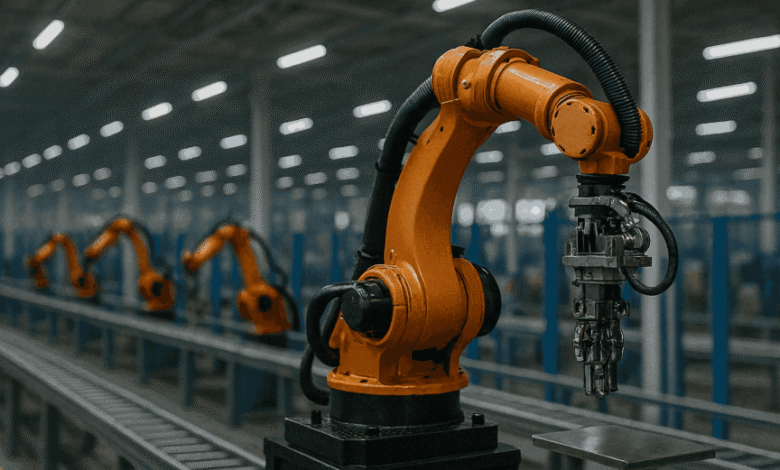

In modern manufacturing, automation is helping businesses work faster, more accurately, and on a larger scale. One of the key innovations driving this change is robotic welding, where programmable robot arms perform welding tasks quickly and precisely. Robotic welding systems are used by companies of all sizes, not just large ones.

As the cost of robots decreases and demand for high-quality, cost-effective production grows, more manufacturers can adopt automation. This helps companies stay competitive, meet customer expectations, and reduce reliance on manual labor. This article explains how robotic welding is changing manufacturing by making work faster, improving weld quality, and keeping workers safer.

What Are Robotic Welding Systems?

These are automated machines with programmable robot arms that perform welding, including arc, MIG, TIG, and laser welding. They can weld and move parts with minimal human involvement.

Main Parts of a Robotic Welding System

Robotic Arm:

The robotic arm is the part that physically moves the welding tool. It follows precise, programmed paths to make accurate welds. Its flexibility allows it to reach different positions and angles needed for various welding tasks.

Controller:

The controller acts as the “brain” of the system. It directs the robotic arm, manages the welding process, and ensures the robot follows the correct instructions for each job. It processes commands from the operator or program and coordinates all parts of the system.

Sensors and Vision Systems:

These components monitor the welding process in real time. Sensors detect position, temperature, and other conditions, while vision systems can scan parts to ensure precise alignment. Together, they help maintain accuracy and high-quality welds.

Welding Power Supply:

The welding power supply provides the energy required for welding. It controls the voltage, current, and type of welding energy delivered to the welding tool, ensuring proper fusion of metals.

These parts work together to allow robotic welding systems to perform fast, precise, and consistent welds with minimal human intervention.

Long-Term Benefits vs. Short-Term Challenges

Starting robotic welding can be challenging because the robots are expensive, and trained operators are needed to run and maintain them. This can be especially hard for smaller businesses.

However, the long-term benefits make the investment worth it:

- Better Quality: Robots deliver precise and consistent welds, reducing errors and producing more reliable products.

- Higher Productivity: Robots can work continuously, allowing companies to produce more in less time.

- Cost Savings: Automation lowers labor costs, reduces material waste, and minimizes mistakes over time.

By overcoming these initial challenges, companies gain a competitive edge, producing higher-quality products more efficiently and safely.

See also: Technofies: Shaping the Future of Education and Technology

How Robotic Welding Systems Are Transforming Manufacturing

Robotic welding systems are transforming manufacturing by changing how products are made and how factories operate. Here’s how they help:

Increasing Efficiency and Productivity

Robots can work nonstop, 24/7, without getting tired. This speeds up production, reduces downtime, and helps factories meet high-demand schedules.

Improving Precision and Consistency

Robots weld with high accuracy, reducing human errors. This ensures all products have the same high-quality welds, which is especially important in industries like automotive and aerospace. Robots also follow exact specifications for complex parts, reducing waste and rework.

Enhancing Workplace Safety

Robots do the dangerous welding work, keeping workers safe from heat, sparks, smoke, and other dangers. This lets people focus on safer jobs like watching the process and checking the quality.

Lowering Costs Over Time

Robotic welding systems can be expensive at first because of the cost of the robots, installation, and operator training. This may be challenging for smaller businesses. However, over time, they save money by cutting labor costs, reducing material waste, and minimizing mistakes.

Supporting Flexibility and Scalability

Modern robots can be reprogrammed to handle different welding tasks and projects. They can also integrate with other smart manufacturing systems, making production more efficient and adaptable to changing needs.

Enabling Innovation

Robotic welding lets manufacturers create more complex designs and handle projects that would be unsafe or difficult for humans, opening the door to innovation and customized production.

Robotic welding boosts speed, quality, safety, and flexibility, helping manufacturers stay competitive and meet the demands of high-volume production.

Key Tasks of a Robotic Welder

Spot Welding

Robots join overlapping metal sheets in car bodies with precise pressure and electrical current. This ensures strong, consistent welds, speeds up production, and reduces costs.

Arc Welding

Robotic arc welding uses extremely hot electric arcs (up to 6,500°F) to fuse metals. It is commonly used in heavy industries such as pipelines and shipbuilding, producing uniform, durable welds that enhance safety and structural strength.

TIG and MIG Welding

Robots perform two types of precise welding:

- TIG Welding: Best suited for thin metals such as aluminum and titanium, TIG welding is commonly used in the aerospace industry to produce precise, high-quality, and clean welds.

- MIG Welding: Fast and efficient, suitable for steel construction, delivering consistent and high-speed welds.

Laser Welding

Robots employ concentrated lasers to produce fast, accurate welds with minimal heat distortion. This is especially useful for delicate electronics and battery assemblies.

Plasma Welding

Robotic plasma welding creates deep, narrow welds on stainless steel and alloys. It is widely used in medical device manufacturing to produce strong, sterile, and reliable joints.

Industries Leading the Shift

Robotic welding systems are transforming industries by making work faster, more precise, and easier to scale. Here’s how different sectors are using them:

Automotive Industry

In car factories, robots perform spot and seam welding with high precision. This makes cars safer, helps production go faster, and ensures every car is made with the same quality.

Aerospace Manufacturing

In aerospace, Robots weld important parts from titanium and aluminum, ensuring they are strong, reliable, and produced quickly while meeting strict quality standards.

Shipbuilding

Robots weld large steel plates and ship structures, delivering higher-quality welds while reducing the need for human labor in dangerous conditions. This allows shipyards to operate faster and more safely.

Construction & Heavy Equipment

Robotic welding is used to fabricate large structural components such as beams, frames, and chassis. It ensures consistent weld quality and minimizes errors, which is important for heavy machinery and infrastructure projects.

Small and Medium Enterprises (SMEs)

Smaller companies are also adopting robotic welding as it becomes more affordable. They benefit from better weld quality, lower labor costs, and the ability to scale production without losing precision.

Robotic welding is helping both large and small manufacturers work faster, safer, and more efficiently. As technology improves, more industries are expected to adopt robotic welding to boost quality and productivity.

Conclusion: Robotic Welding Systems

Robotic welding systems improve manufacturing by increasing speed, precision, safety, and flexibility. Despite high initial costs and the need for trained operators, their long-term benefits make them a valuable investment. These robots can perform many types of welding, like spot, arc, TIG, MIG, laser, and plasma, in industries such as automotive, aerospace, shipbuilding, construction, and even smaller businesses.

By handling dangerous or repetitive tasks, they protect workers, ensure consistent quality, reduce mistakes, and enable more complex and innovative designs. Robotic welding helps manufacturers stay competitive, increase production, maintain high quality, and meet growing demand. As technology advances and costs continue to drop, robotic welding is becoming an essential tool for modern manufacturing across companies of all sizes.